The vast problem of marine litter is incredibly complex, stemming from various sources and at multiple levels. So naturally, the ideas proposed to solve this problem are just as diverse.

In the following section of the exhibition, on display are ideas that tackle the problem of marine litter. There is a broad spectrum of ideas when discussing the future, and countless fantastic propositions dealing with the problem that have been around for quite some time: from rethinking the design and material of everyday objects to discussing different recycling systems and their implementation. Reducing the use of plastic in one’s everyday life is a great starting point, as is joining cleanups that take place on beaches or at rivers, or getting involved politically in the fight for a sustainable garbage disposal system. On a broader political level, jurisdictional decisions affecting ocean laws will play a key role in solving the crisis of plastics in the ocean.

One way to get the plastic out of the ocean and put it to a new use is Recovery. This strategy includes, for example, collecting fishing nets abandoned at sea and feeding them into a type of recycling process in order to generate new raw material. A way of avoiding plastic garbage in the sea is to think differently about designing with plastic as a material (Redesign) or to avoid using it in the first place (Remove). If plastic is indeed used in the manufacture of products, the best course of action is to keep that plastic in the production cycle, which means having a functioning infrastructure for Recycling the material and for its continuing use for new products. Another way to deal with the material is not recycling it in a conventional sense (in other words, breaking it back down to the raw material), but to Reuse the plastic material in its end-of-use state and transform it into something else. And there are of course a variety of methods to Reduce plastic waste: in the form of theoretical concepts for end-of-life-use and in the form of laws that, for example, forbid the sale of plastic bags, or pushing initiatives seeking a stricter international common ground in the field of maritime law.

Using less plastic in the first place and disposing of it properly so that it can be recycled are key actions for keeping the ocean free of plastic garbage.

Recover

The concept of Recover is to collect materials such as plastic bottles and fishing nets which are already lost at sea and recycle them. New “raw” materials procured from this process, such as nylon, can then be reused in new products. Numerous products are currently made from recovered materials, such as drinking bottles, detergent or shampoo containers, and fashion products like shoes, bags, and jackets.

Projects such as The Ocean Cleanup, in which a vessel is sent out to collect plastic garbage from the marine surface, have received a great deal of media attention. In addition to this by now well-known project, there are also initiatives such as the crowdfunded Seabin Project by Australian surfers who are personally invested in cleaning the ocean’s surface. Removing (and reusing) the larger pieces of plastic from the ocean will undoubtedly have a great impact on the ocean’s health, but the challenge of capturing microplastics and the plastic that has sunk to the seafloor has yet to be dealt with.

Recovery collaborations like those of Parley for the Oceans with Adidas, which produced a shoe made of recovered plastic flotsam, and H&M, which launched a collection made of recovered plastic, put into action the idea of making use of the materials taken back from the sea. In addition, many cosmetic companies are following a current trend to manufacture their containers from plastic bottles—whether recovered or recycled.

Though products from large companies often generate media attention, they unfortunately have minimal impact on overall production and the consumer market (and thus on the actual amount of material recovered from the sea). Limited in scale and prohibitively expensive, these products and their launch may indeed reach the mass media, but they are not contributing to the solution on a real-world level. Quite often it is the smaller labels who make a genuine commitment to the challenge of using recovered materials. A selection of those brands can be discovered in this section of the exhibition. While some of these initiatives might be “under the radar” on a global market scale, they are still transmitting ideas that represent crucial game-changing moments. Many of these ideas are meant to inspire and later taken up in other products and by other companies. And some incorporate a wider social component into their efforts to clean the oceans, seeking to bring positive change to local communities that depend on the sea for their livelihood. Hopefully, over the coming years many more projects, products, and political options will surface and begin contributing to solving the worldwide crisis of plastic garbage in the oceans.

Ghost Fishing Nets

provided by Healthy Seas

Healthy Seas - a Journey from Waste to Wear is an initiative active in several European countries and dedicated to connecting different stakeholders in the struggle for ghost net free seas and oceans. Involving local divers and fishermen in the process of collecting waste fishing nets lost at sea or discarding their own used nets in one of the containers provided by Healthy Seas in different locations, they contribute to a cleaner sea right at the source.

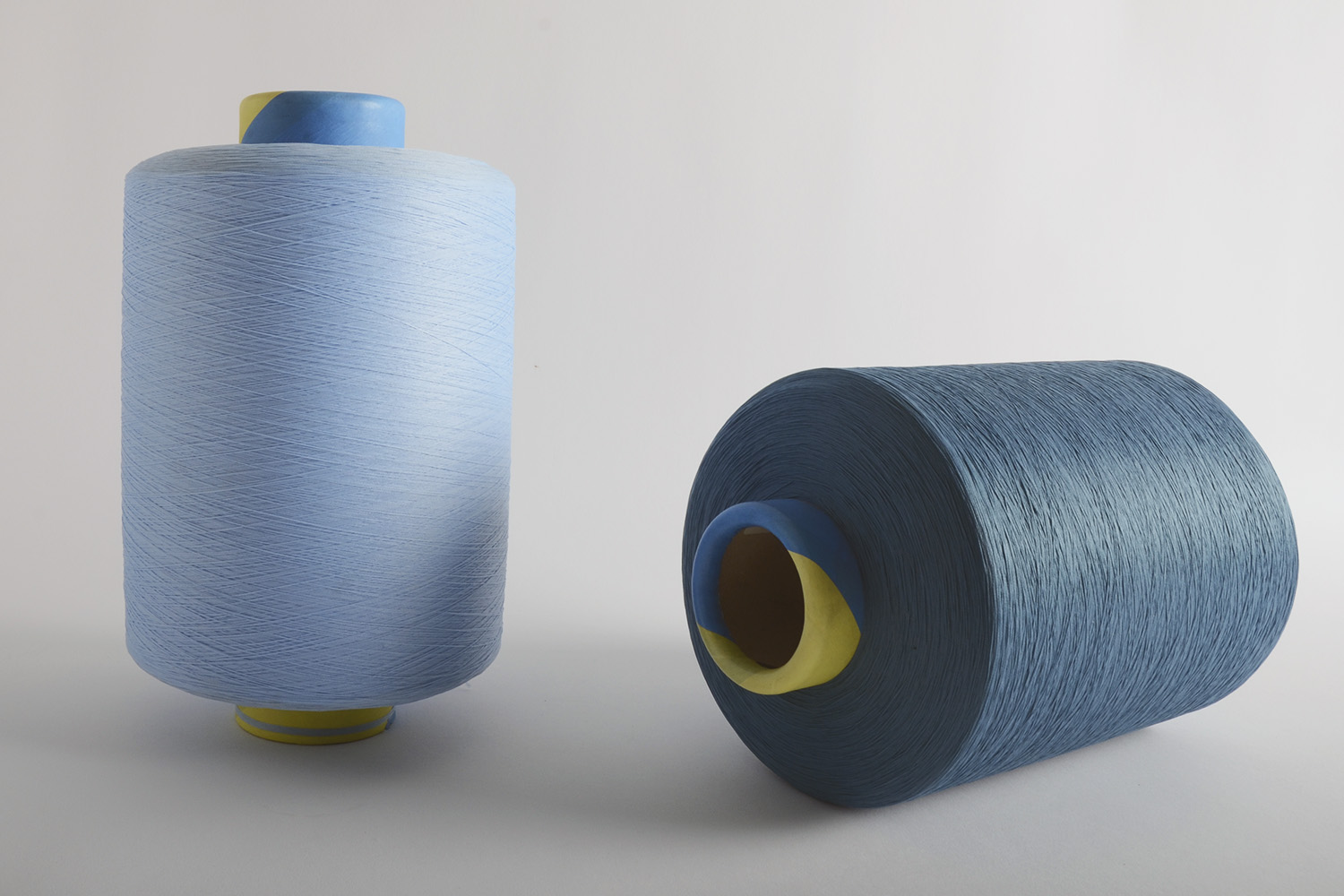

Providing new material for new products to be made (in this case, the fishing nets), they also collaborate with manufacturers such as Aquafil, a company regenerating nylon yarn from those discarded fishing nets. This yarn is then used by other companies to make products such as bathing suits, socks, and so on. These companies then become part of the extensive Healthy Seas network.

Earthrise: Fish Net Fashion

Al Jazeera, 2015

Film, 12:02 min

Recycled Raw Material

ECONYL® nylon yarn from Aquafil

Recovered Products

In addition to Healthy Seas, there are many other initiatives and brands working with recovered fishing nets: Chile-based skateboard company Bureo uses the material from locally collected fishing nets to produce skateboard decks and sunglasses. Fashion brand Ecoalf also collects and uses discarded fishing nets for some of their products.

Socks by Healthy Seas

Recovered Product

Swimwear by Summerlove

Recovered Product

Swimwear by Woodlike Oceans

Recovered Product

Skateboard and sunglasses by Bureo

Recovered Products

ECOALF Aspen jacket in black and Ushuaia jacket in blue

Recovered Product

Net-Works

Net-Works is an initiative working with coastal communities in places such as the Danajon Bank in the Philippines to combat marine litter in a very unique way. Since a lot of communities depend on the fishing industry, an industry greatly harmed by plastic garbage and “ghost nets” (lost or abandoned fishing equipment) in particular, Net-Works offers an alternative for the fishing communities to earn their livelihood: fishing for nets that can then be used in a recycling process to generate new raw material. This material is subsequently transformed into nylon yarn and used for producing carpet tile at the company Interface.

Net-Works is not only providing an alternative source of income for fishing communities, but it is also helping to develop a type of infrastructure by organizing the establishment of small banking systems.

Animation Film Net-Works

2:10Min

Interface | The Net-Works programme: A Second Life for Discarded Fishing Nets

2013; Film 7:45 min.

Interface | Net-Works: turning waste nets into carpets

2014; Film 4:21 min.

Redesign / Remove

Many typical plastic products like plastic bottles and bags can be easily replaced with products made from other materials. Steel or glass bottles, for example, provide a reusable alternative to single-use plastic bottles. As are bags made of cloth to plastic bags. Often the main difficulty lies in thinking ahead and, for example, making sure you bring your own bag for shopping.

In the “take-away” culture of fast consumption, it is often a question of training yourself to resist the easy solution of plastic packaging and making a sustainable choice.

This goes for consumers as much as for stores, restaurants, and others that provide goods. While producers can change a great deal at the outset, individuals and consumers have the power of decision and can choose a sustainable alternative over a single-use product. Just think about it: a plastic food container might be used for a total of five minutes but may last for up to 450 years if not disposed of properly. And 40 percent of all plastic produced is destined for use as packaging material.

Another way of rethinking the use of plastic is to design products that are reusable and/or easy to recycle right from the start. Products composed of only one type of plastic is much easier to recycle then those made of various types, which it may not even be possible to separate out. Problems arise when plastic types are mixed together or receive a specific color. These products often cannot be separated and recycled, even if disposed of properly. With a single-type plastic, however, one can attain an as-good-as-new material after recycling. And, of course, if durable plastics are used, a product can be used over and over again.

HYDROPHIL TOOTHBRUSHES

Made out of bamboo

Reusable Totsbots nappies

provided for the exhibition by ValleMonte

A toothbrush is one product traditionally made of plastic. But there are alternatives.

Bamboo, for example, is a fast-growing natural resource that works just as well. If you break up the head of the toothbrush before disposing of it, the rest of the product can biodegrade just fine.

Another example of the redesign of a traditional plastic package for products such as shampoo considers the durability of the product: imagine a long-lasting, refillable design for your daily cosmetic products to be stored in. And if the bottle is designed as just one item without any more components (and thus made of just one kind of plastic), it is easy to recycle it at the end of its useful life. And if one prefers a more traditional approach: there are many soaps available, that come without any packaging at all.

Nephentes

A single component shampoo bottle designed by Marilu Valente

Instead of using plastic cups and cutlery at your next party, why not choose single-use paperware that can indeed biodegrade? Or use products that can even be used several times?

And if you go shopping, just pack your cloth bag before you go to the store. It is more durable, looks better, and can be used countless times.

The same goes for plastic bottles: take a glass bottle instead and use it again and again.

And, of course, if you are on the production side or responsible for a store or restaurant, you can have an immense impact with your choices. You can think of a different design or material for products, you can choose not to sell or provide plastic bags in your store, or you can devise alternatives to traditional food to-go packaging for your customers.

Camping flatware

by Ecosoulifemade out of biodegradable bamboo

WASARA tableware

made out of compostable materials (sugarcane waste and bamboo)

Glass bottle by Soulbottles

0,6 Liter / made out of glass, natural rubber, ceramic, stainless steel / various designs

Reuse / Recycle

If disposed of and recycled properly, plastics can have various life cycles and be used repeatedly. There are numerous ways by which the useful life of even a disposable plastic bottle can be prolonged.

But research shows that almost half the plastic garbage that is produced all over the world is mismanaged in its disposal and thus cannot be recycled. Ultimately, this is one of the main factors causing the grim forecast that in 2050 there will be more plastic parts then fish in the ocean.

One way of reusing plastic is to take the material that otherwise would be thrown away and transform it into something else. One does need to literally recycle the material to bring it to new use. Many do-it-yourself concepts work with plastic materials, and many companies work with this same idea on a larger scale.

Recycling typically turns used material into “as-good-as-new” material in the sense of a reusable raw material that can be transformed into any other new product. Sometimes the material attained from the process is of lesser quality that the original material but still good enough to use for certain products. This is called Downcycling. In addition, material sorting technology has made great progress, making it is possible to separate the various plastic types into mono-material sections. This means that the quality of the original material can typically be well maintained.

Therefore, if the infrastructure for collecting the plastic garbage is provided, the recycling process can be both very effective and incredibly fruitful. Unfortunately, in many countries the correct collection and separation of garbage is simply not yet possible.

Freitag Bags

Since 1993 FREITAG is producing bags from used truck tarps. The FREITAG headquarters are in Zurich Oerlikon where the tarps are disjointed, cleaned and cut.

There are five tarp buyers – also known as truck spotters – hunting down the best tarps in the hottest colors to work with. They find and bring back approximately 390 tons of used tarps from truckers and shipping companies to the FREITAG factory each year.

First, the tarps are freed of eyelets, straps, belts and anything else that a FREITAG bag doesn’t need. With a sharp knife, the tarps are cut into standardized 7.8-foot pieces, folded together and send them off to the Laundry Department.

Washing the tarps ans washed tarps.

The Bag Designers fashion each individual bag by using their templates and cutters to carve the most beautiful designs possible from the tarps and then making sure that the rest of the pieces match as well.

Finishing and storing the bags.

The Bag in the Spotlight.

© All photographs: Joël Tettamanti

F49 FRINGE, Backpack, FREITAGlab. ag

Materials used: used truck tarpaulins; used car seat belts

F12 DRAGNET, Messenger Bag, FREITAG lab ag.

Materials used: used truck tarpaulins; used car seat belts; bicycle inner tubes

Recycling

Plastics are produced from mineral oil and, despite their low price, are a valuable product. In the words of PlasticsEurope (European Association of Plastics Manufacturers):

“They are too valuable to be thrown away.”

Essentially, almost all plastics are reusable. The best recycling solutions available are those for materials of a single sort. Where different kinds of plastic are mixed the processes are more complex.

Feedstock recycling

Feedstock recycling describes chemical and thermal processes by means of which monomers, gases or oils can be recovered. These raw materials can then be used for the production of new plastics. In contrast to mechanical recycling, feedstock recycling can also be used for mixes of different plastics. The disadvantage is the high expenditure of energy involved in such processes. Feedstock recycling is still largely at the pilot stage. It remains to be seen whether such processes can ever become successfully established.

Mechanical recycling

As the name suggests mechanical recycling is a mechanical process in which plastics are sorted, crushed, washed and processed into what is called regrind. It is most important that the processing should be clean and use just a single material. Where this is not the case quality declines and the regrind can only be used for technically less demanding secondary products

Energy recovery

In energy recovery plastic is used as a substitute fuel. The calorific value of plastics is similar to that of black coal or heating oil. Energy recovery is used in industry. Energy recovery also takes place in waste incineration plants in the form of power production and utilization of heat.

Der Grüne Punkt – Duales System Deutschland GmbH

Film, 3 mins., 30 secs.

The PET cycle

The polyethylenterephthalate bottle which has been developed since the 1960s and began its world career in 1978 with the two-liter Coca Cola bottle, has by now almost completely replaced the traditional (reusable) glass bottle. In the material cycle of a PET bottle recycling is the central theme. In a number of countries, there a deposit is charged on PET bottles to promote higher return rates. Some of the bottles are processed to make new PET bottles. In addition textiles and packaging material are made out of recycled PET fibers.

The typical cycle of a PET bottle:

→ 75% PET granulate and 25% recycled PET (rPET)

→ PET blank

→ PET retail bottle

→ PET-bottle after use

→ PET flakes from recycled PET

→ PET Preforms

PET Granulate Flakes

provided by PolyRecycling

PET Preforms

provided by RESILUX

Downcycling

The problem about the recycling of plastics is that it generally takes the form of downcycling. The reuse of the material means a reduction of the original quality. The regrind plastic produced in the recycling process is used for less valuable products such as park benches, bollards, watering cans and containers. In addition this processing often involves mixing with other materials. The new products created are thus eliminated from the cycle of pure materials.

California Sneakers

Ecoalf

Munich Backpack

Ecoalf

FlippFlops

Ecoalf

Bag

made out of plastic bags turned into thread and then woven

KHAMIR Craft Resource Centre, Kachchh, Gujart, India

Upcycling

Upcycling means the production of a new and more valuable product out of old things. This is not an industrial form of processing but an alternative strategy that is employed by designers and others. For example new satchels are produced from old truck tarpaulins, or flower pots out of yoghurt beakers. Solutions of this kind harbor enormous creative potential and produce an ecological and social profit. However, the way to waste incineration cannot be avoided, simply delayed.

Reduce

Reducing in the context of marine litter means two things:

one, reducing the use of plastic itself;

and two, reducing the amount of plastic residue entering the oceans.

The reduction of plastic waste is strongly connected to the idea of recycling and reuse. One potentially influential basic concept is actually designing products to be repeatedly reused. This could mean that in the future you might not simply buy something and then discard it but perhaps actually rent it and then return it to the producer for proper disposal and recycling.

Another way of reducing plastic waste reaching the oceans is to refuse plastic goods in the first place and whenever possible.

Reducing the use of plastic can also be promoted through government intervention, whether passively through the raising of taxes on the use of certain materials, or more actively through prohibitions on their use. But governments can also make a huge impact through garbage management. If a functioning system of waste management and recycling is provided, then the amount of plastic entering the ocean from land will undoubtedly decrease. The same applies to maritime law, where mandatory rules are necessary for the proper handling of waste on the open seas. One of the most influential examples in this context is the International Convention for the Prevention of Pollution from Ships (MARPOL). Put into practice in 1973 and since updated several times, it is the main international convention covering the prevention of pollution of the marine environment by ships from operational or accidental causes.

The concept of a circular economy

A circular economy is restorative and regenerative by design and aims to keep products, components, and materials at their highest utility and value at all times. The concept distinguishes between technical and biological cycles.

As envisioned by the originators, a circular economy is a continuous positive development cycle that preserves and enhances natural capital, optimizes resource yields, and minimizes system risks by managing finite stocks and renewable flows. It works effectively at every scale.

Circular Economy System Diagram

Ellen MacArthur Foundation

How do we get rid of the off the problem of plastic bags in the ocean?

Despite of course a proper disposal of the used bags, one can already start at production and distribution: Different states have different approaches to these matters. In India the very thin, single-use plastic bags are entirely banned whereas countries like Germany forbid from giving away plastic bags for free and make stores charge customers for it. But really, change can come from the consumer by not using plastic bags.